Rubber Bellows are elastic joints that can expand and compress while maintaining a permanent seal. They are used to protect moving mechanical parts from dirt, allowing them to last longer. At Barbieri Rubber we design and manufacture Rubber Bellows, of all types for a variety of industries and uses.

Rubber bellows, what they are and what they need for

Rubber bellows provide the perfect protection for unlimited combinations of items and uses. They are a very useful safeguard tool in multiple industrial and civil areas. Their main use is to increase the durability of moving parts and organs by protecting them from contact with other parts as well as from external elements such as dust and impurities.

Rubber Bellows of all types for a variety of industries and uses

Rubber bellows can be used to protect innumerable types of mechanical organs and parts, both static and moving, without restricting their motion, such as: industrial machinery, operating machines, hydraulic and pneumatic cylinders, transmission joints, guides and worm screws, doors and window frames; or for example, they can protect the cable passage between vehicle doors and chassis, the passage of compressed air hoses, etc. Sometimes they can serve as a pipe, conduit or even an expansion joint. But their primary use is as protective covers. The fields of application are extremely wide.

Rubber bellows can be made in a variety of shapes and sizes and can be used to protect different types of motion, such as: axial, angular, or dynamic. They have a small thickness and are particularly suitable and convenient in conditions where the following are needed: protection at small dimensions, waterproofness, resistance to a wide range of temperatures, and very high operating speeds. They have a wide measurement range from full extended to full retracted.

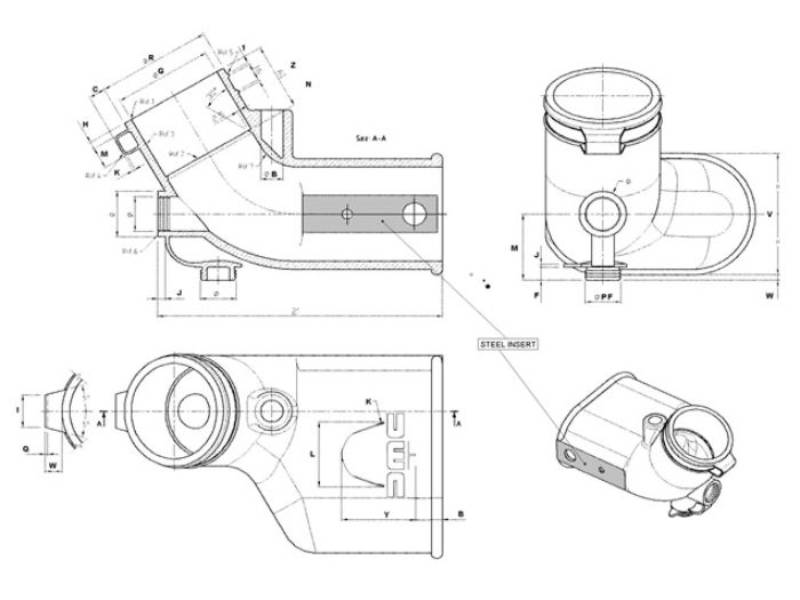

Rubber bellows, design and manufacturing

We directly design our own items and cooperate with the Client in co-design. We provide our experience through highly qualified and skilled professional staff, state-of-the-art technical and testing equipment and high design know-how.

Rubber bellows are produced by molding, mostly by injection, but also by compression, using special molds. They consist of a single piece, with the exception of Modular Bellows, which consist of the bellows body, end collars and joints, which allow the bellows to be connected to each other and obtain lengths that cannot be achieved by molding.

Rubber molding requires special Know-how, which at Barbierirubber we have been able to boast for two entrepreneurial generations and which is now an intrinsic feature of the company, thanks to two established Quality Certifications: the ISO 9001:2015 and the IATF 16949:2016. Go to the Certificates.

In Barbierirubber, we have different types and sizes of machinery for the production of rubber bellows; this allows us to be able to meet the needs of our Customers in all industries markets and type of use.

Rubber bellows applications

The needs of rubber bellows users are constantly changing as the features required by machinery and equipment manufacturers become more sophisticated, or as the applications and uses change.

Rubber bellows can be made in various compounds depending on specifications; for example, in some application areas resistance to oil, grease and hydrocarbons is required; or resistance to weathering such as air, wind, rain and sun exposure. It all depends on the end characteristics and specific uses.

Main Article Categories

We design and manufacture Molded Rubber Bellows, Standard and Custom Rubber Articles of any types for many industrial and civil sectors and multiple uses.

Barbieri Rubber. Contact us for more information.

Tel: +39 0522 550433 | Mail: sales@barbierirubber.it